Every body panel on Frank Livingston’s ’49 Mercury was reworked by metal master Paul Bragg. This article shows what was needed to create this styling masterpiece.

Paul

Bragg has been building custom cars for many decades. He is world wide

known for his fantastic metal working skills and excellent taste in

Custom Car design. Paul combines his metal working skills with an very

good eye for proportions, lines and style. Allowing him to

modify virtually anything he feels is needed for the perfect custom.

Paul has restyled a lot of ’49 – ’51 Mercury’s, and each of them

styled differently, and chopped in way that fits that particular

restyled car the best. We will devote several articles about Paul, and

the wonderful Custom Cars he creates, stay tuned. This first article is

about an extensively restyled 1949 Mercury Paul built for Frank

Livingston.

Before

starting to cut up a car, Paul usually makes a few sketches of what he

has in mind for a particular car. It helps him to see if all the design

elements work together but it also allows the client to see which

direction Paul has planned for them.

Before

starting to cut up a car, Paul usually makes a few sketches of what he

has in mind for a particular car. It helps him to see if all the design

elements work together but it also allows the client to see which

direction Paul has planned for them.Frank Livingston is no stranger when itmcomes to Custom Cars. Ever since the mid 1950′s Frank has owned Custom Cars, some of them were famous, made the magazines and even some covers. He showed his car at many famous car shows. And Frank is still at it today, very active promoting and enjoying Custom Cars. In the early 1990′s Frank had his most restyled custom to date, a ’49 Mercury named “Moon Fire” built by some of the top shops in the field, including Paul Bragg Rods & Customs out of Paso Robles in California.

The top

Frank Livingston approuched Paul Bragg for a new custom based on his ’49 Mercury they discussed what could and needed to be done to the car. Paul had a very clear vision how the car should look. He made several sketches to show Frank what he had mind. What Paul had in mind was not your average “basic” custom job. The sketched showed that nearly every body panel would need to be reshaped to match the sketches. When both approved on how the car should end up looking it was time to start cutting up the Mercury body. Paul started with chopping the top, he removed 4.5 inches from the front and nearly 6 inches from the C-pillars. Paul removed the drip rails, and leaned the B-pillars forward. At the back he removed the stock rear window, and most of the surrounding metal. He used an ’49 Chrysler rear window reshaped the rear quarter windows and hand formed the complete rear portion of the roof and turret panel. The end result is an unique shaped top that flows gently towards the trunk and has perfect proportions from every angle you look at it. The Plymouth rear window fitted better with the trunk changes Paul had in mind for the car. Going for the smoothed look Paul decided the belt line trim had to go as well, and the sharp edge was filled in and smoothed. An old trick the Ayala’s and Barris shops also loved to do. This

photo taken in the early stages shows how Paul incorporated the ’49

Chrysler rear window. And how much new shaped metal was needed to get

the desired look. Also not the sharp edge where the belt line trim used

to be.

This

photo taken in the early stages shows how Paul incorporated the ’49

Chrysler rear window. And how much new shaped metal was needed to get

the desired look. Also not the sharp edge where the belt line trim used

to be. The

metal work on the top portion of the car is all done, and paul is ready

to apply the first coats of primer. Take a close look at the flow of

this top, and notice the molded in and smoothed belt line.

The

metal work on the top portion of the car is all done, and paul is ready

to apply the first coats of primer. Take a close look at the flow of

this top, and notice the molded in and smoothed belt line.The sides

With the top portion of the car in primer it was time to move to the lower parts of the car that needed to be restyled. The front wheel openings were lipped using the wheel opening from an ’55 Plymouth. At the rocker panels Paul created a hand shaped panel to extend this lip from the front wheel opening all the way to rear quarters where it would end at the leading edge of a custom made forward angled scoop. The angle of the scoop is set at the same angle as the B-Pillar. Paul originally planned to update the side trim with a much wider ’53 Mercury unit. And shaped the scoop top leading edge to follow the bottom edge of the side trim closely. At a later stage Frank decided he did not like the heavy trim and asked Paul to add a much thinner unit.Paul wanted flush fitted skirts on the car, but decided they needed to be much longer than on the stock rear wheel opening mercury. So he cut out a little oversized section from the rear quarter panel, he then formed a metal lip to finish the new opening. But before he welded that into place, he used this lip to shape the new flush fit fender skirts first in wire, and later,in sheet metal. Once the skirts were up to Pauls’s standards he welded the lip to the rear quarters. Paul created a set of wonderfully styled larger flish fitting fender skirts.

The new opening lip for the rear wheel opening was used to shape a wire frame for the new flush fitting skirts.

The new opening lip for the rear wheel opening was used to shape a wire frame for the new flush fitting skirts.  The

metal lip has now been welded to the enlarged and reshaped opening.

Notice the quarter panel scoop and how the angle matches the B-Pillar.

The

metal lip has now been welded to the enlarged and reshaped opening.

Notice the quarter panel scoop and how the angle matches the B-Pillar. The back side of the hand made passenger side fender skirt.

The back side of the hand made passenger side fender skirt. The finished skirts in place.

The finished skirts in place.The rear

Paul then moved further back and started there with the rear bumper. Paul used a 1951 Mercury front bumper and reshaped it to fit flush with the body. He used a narrowed 1955 Pontiac license plate cover and molded that onto the bumper. Next he created a flush fitting splash pan that followed the shape of the bumper including the raised center section. This raised center section would be the base for the recessed section on the trunk The top portion of the recess was shaped into a scoop with similar styling as the quarter panel scoops. The shape of the molded in splash pan was extended to the sides of the body where they would follow the ends pieces of the ’51 Mercury bumper. The Mercury body line extending from the front fenders was extended horizontal towards the rear where it falls down to the bottom on a stock Mercury. This extended section was the base for the hand shaped three part taillights. Paul also moved the so called “dog leg” dip in the doors towards the back of the door. Making the dip much less pronounced. Most

of the hard body work on the rear section is completed in this photo.

The trunk was heavily reshaped with rounded corners and cut out to folow

the shape of the custom bumper. This bumper will fit flush in the new

opening created for it.

Most

of the hard body work on the rear section is completed in this photo.

The trunk was heavily reshaped with rounded corners and cut out to folow

the shape of the custom bumper. This bumper will fit flush in the new

opening created for it.The front

The body work done so far was prepped and a few coats of primer were added to seal the work. It was now time to move to the front of the car. Here a lot of work was needed to make Paul’s ideas come to live in metal. Paul started with narrowing a ’51 Mercury bumper and move it forward from the stock bumper position. This forward position of the bumper would be the base for everything else done on the front of the car. Paul welded the headlight bezels to the front fenders a few inches forward from its stock position. He then used cardboard to figure out the metal shapes he needed to create for the new extended fender shapes. The section below the headlights was angled forward at the same angle as the B-Pillar. A new splash pan was created that would fit on top of the bumper. The splash pan would folow the shape of the bumper in a similar way as was done on the rear bumper and would flow nicely into the new lipped front wheel openings.Paul hand made a new grille opening with shapes inspired from the Hirohata Mercury. The hood was extended down and would incorporate the lipped grille opening center section. At the back of the hood the ends were cut of and welded to the front fenders and top of the cowl. All corners on the car were rounded and with all the new elements roughed in shape it was time to metal finish the last sections of the car before Paul would add more primer to the whole car.

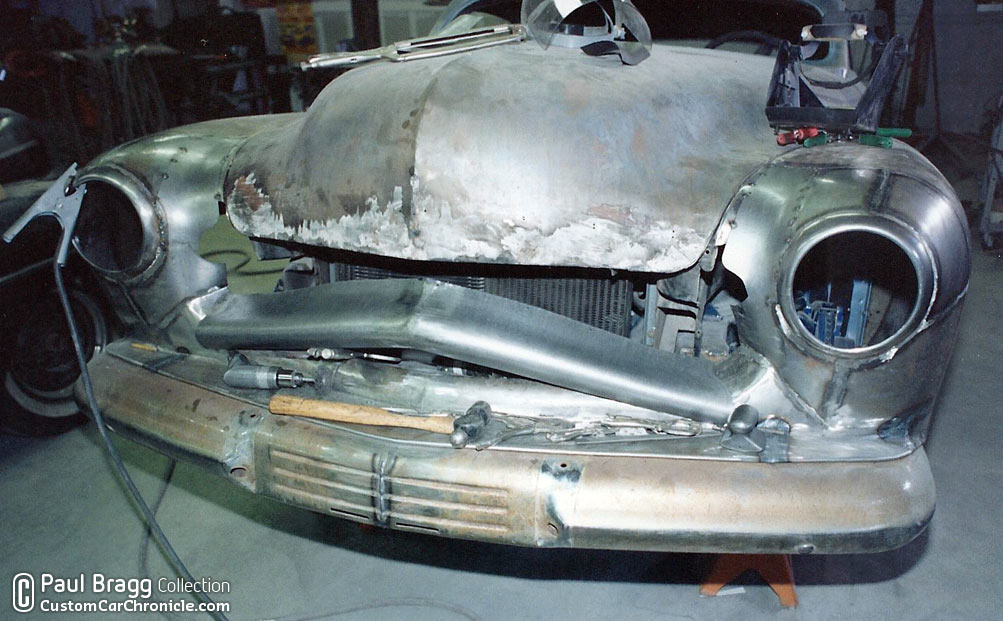

The

forward mounted narrowed ’1951 mercury front bumper. The ’55 Plymouth

lipped front wheel openings are already in place here. The Plymouth

lipped opening have a more gentle curve than the often used 1952-54

Mercury units.

The

forward mounted narrowed ’1951 mercury front bumper. The ’55 Plymouth

lipped front wheel openings are already in place here. The Plymouth

lipped opening have a more gentle curve than the often used 1952-54

Mercury units. The

front fenders were extended by welding the headlight bezels to wire

rods welded to the fenders. The cardboard templates were later

transferred to sheet metal which were shaped to fit. The center section

of the new splash pan can also be seen in this photo. Notice how it

overlaps the front bumper, and how a nice rolled end was already created

for a nice finish look.

The

front fenders were extended by welding the headlight bezels to wire

rods welded to the fenders. The cardboard templates were later

transferred to sheet metal which were shaped to fit. The center section

of the new splash pan can also be seen in this photo. Notice how it

overlaps the front bumper, and how a nice rolled end was already created

for a nice finish look. Half of the new shaped front section of the front fenders is in place now.

Half of the new shaped front section of the front fenders is in place now. All body work on the mercury was hammer welded and metal finished.

All body work on the mercury was hammer welded and metal finished. With

the work on the extended fenders done it was time to start shaping the

new grille opening. In this photo the bottom portion is already welded

in place. The top portion is shaped, but not in place yet.

With

the work on the extended fenders done it was time to start shaping the

new grille opening. In this photo the bottom portion is already welded

in place. The top portion is shaped, but not in place yet. The top portion is now in place and the hood section is cut of and the ends filled in.

The top portion is now in place and the hood section is cut of and the ends filled in. The whole restyled front end is finished and now its time for lead and metal finish to perfection.

The whole restyled front end is finished and now its time for lead and metal finish to perfection. Leaded and sanded smooth. Notice the wonderful curves and shaped of the restyled elements.

Leaded and sanded smooth. Notice the wonderful curves and shaped of the restyled elements.

This photo shows the work done on the back side of the hood as well as the work on the rocker panels that flow into the lipped front wheel opening on the front and the scoop at the rear.

The finished car

After Paul Bragg’s work on Frank’s Mercury was finished and the car was in primer Frank took the car to Bill Reasoner in Walnut Creek, for the pearl aqua blue paint job Paul created a custom grille from bumper guards and 1953 Mercury bullets and customized a set of 1953 Cadillac hubcaps. After Bill Reasoner was done painting the car, Frank took the car to Jerry Sahagon for a custom interior.The Finished mercury is a great example of wonderful custom restyling. Basically no panel was left untouched to create this Paul Bragg masterpiece. It hints to the early Customizers Ayala and Barris brothers, but also incorporates Paul Bragg’s personal styling elements and modern details. The Paul Bragg Livingston Merc is a true masterpiece. Paul

reshaped the ’51 Mercury front bumper by narrowing it to fit flush with

the fnders and adding a new center section created for a second ’51

Mercury bumper. The grille is a work of art in itself as well. (Frank Paul photo)

Paul

reshaped the ’51 Mercury front bumper by narrowing it to fit flush with

the fnders and adding a new center section created for a second ’51

Mercury bumper. The grille is a work of art in itself as well. (Frank Paul photo) The

flow of the new top, the reshaped rear quarter windows and angled

forward B-Pillars look particularly nice from this rear 3/4 angle. (Frank Paul photo)

The

flow of the new top, the reshaped rear quarter windows and angled

forward B-Pillars look particularly nice from this rear 3/4 angle. (Frank Paul photo) Paul even restyled the ’53 Cadillac hubcaps with custom made center sections. (Frank Paul photo)

Paul even restyled the ’53 Cadillac hubcaps with custom made center sections. (Frank Paul photo) A

good look at the rear of the car showed the wonderful reshaped ’51

Mercury front bumper and how its shape extends into the rear quarter

panels.This photo also shows how the lip of the front wheel opening

flows into the rocker panel.

A

good look at the rear of the car showed the wonderful reshaped ’51

Mercury front bumper and how its shape extends into the rear quarter

panels.This photo also shows how the lip of the front wheel opening

flows into the rocker panel. Everything on Frank’s Mercury flows and all the lines are there for a reason.

Everything on Frank’s Mercury flows and all the lines are there for a reason. The Mercury at the Sacramento Autorama where the car was a huge crowd pleaser.

The Mercury at the Sacramento Autorama where the car was a huge crowd pleaser.  Frank Livingston polishing and detailing the grille on set up day of the Sacramento Autorama.

Frank Livingston polishing and detailing the grille on set up day of the Sacramento Autorama. Source: customcarchronicles.com